Logic+ System Troubleshooting Manual

Logic+ System Troubleshooting Manual

If you’re looking for information about the Logic+ (Plus) System Boiler, you’re in the right place. The Ideal Heating team has collected key information about this efficient condensing model, helping you get to the bottom of any queries you might have about your boiler.

Among the information you’ll find below is a guide to your boiler’s controls, explanations for its display codes, and a simple-to-follow troubleshooting guide. You’ll also find a PDF download for the complete user manual to answer any more questions you may have.

Introducing the Logic+ System Boiler

The Logic+ is a system boiler, which is the name for models that use a hot water cylinder to provide central heating and hot water to our homes. The Logic+ has been approved by the Energy Saving Trust, so you can rely on it to heat your home efficiently.

The Logic+ System Boiler’s Controls

The handy image below explains the layout of your Logic+ System boiler’s control panel, which you can refer back to as you read through this page.

How to Operate Your Logic+ System Boiler Efficiently

This model is a modern and efficient condensing boiler, which will change its output depending on whether it’s being called on to produce more or less heat for your home. When it lowers the amount of energy it’s using, that will lead to less expensive utility bills.

To increase your boilers efficiency, simply adjust the central heating temperature knob (H) to the ‘e‘ position or lower. In the colder months, you may find you need to turn the knob towards the ‘MAX’ setting as your boiler will likely be seeing more demand for heat.

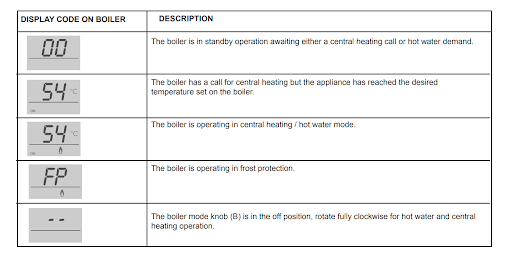

Logic+ System Boiler Display Codes

Your boiler will display a number of different display codes, depending on several factors. In the table below you’ll find some common display codes for the Logic+ System boiler, together with a brief description of their meaning.

Managing Your Boiler’s System Water Pressure

You can use the pressure gauge (G) to monitor the pressure of your boiler. If the pressure falls below 1-2 bar (the original installation pressure), or is doing so repeatedly, there could be a water leak in your system.

To repressurise your Logic+ System to 1 bar, use the boiler’s filling loop to allow water in from the mains. Keep a close eye on the pressure and turn off the tap when it reaches 1 bar, then press the “RESTART” button. For more advice or assistance carrying out this task, speak to your installer for further information.

Speak to a Gas Safe registered engineer if you continue to have issues with your water pressure or need more support to tackle this issue.

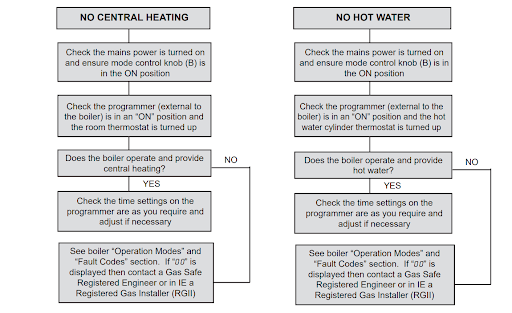

Troubleshooting the Logic+ System

If you ever find that your boiler is failing to provide either central heating or hot water, simply follow the steps laid out in the table below.

If necessary, you can download a PDF user guide at the bottom of this page to find a full list of fault and display codes.

How to Restart Your Logic+ System Boiler

If your boiler displays a fault code and you need to restart it, all you need to do is press the RESTART button to prompt your boiler to repeat its ignition sequence. If pressing the button fails to work, contact a Gas Safe registered engineer for further assistance.

Keeping Your Logic+ System Boiler Clean

If you want to keep your boiler looking like new, it’s a simple job to leave it clean and tidy — dusting the appliance with a dry cloth will provide the best results. If you have difficulty with a stubborn stain or mark, try wiping it with a non-abrasive damp material.

For a full explanation of all fault codes and even more useful information about your boiler, download the PDF of the Logic+ System Boiler user guide.

Keep your Logic+ System Boiler in the best condition by registering your warranty with Ideal Heating and arranging a service at least once a year with a Gas Safe registered engineer.